About

Quick Bio

I grew up in a house where there were always interesting projects in the garage and new ideas were encouraged. When my kids were born, I became an at-home dad and invested my time working with my kids, trying to promote the same environment I grew up in. Now that my two kids are out of the house, I wanted to create a product worthy of putting my name on.

Over the years I've noticed many people have beautiful bars but keep their barware hidden in drawers. Being an admirer of custom knife makers, I wanted to combine the process and materials with barware. I started creating pieces of functional art worthy of being displayed on the bar top.

Process

I mainly use 1/8-in AEB-L stainless steel for corrosion resistance and magnetic properties once heat treated. Upon customer request, I have used a variety of damacus steels.

My heat treat process was refined to bring out the best of the materials used. Realizing it's overkill for a bottle opener, I am following the same process used for knife making. The goal of this process is to make a product that will last a lifetime.

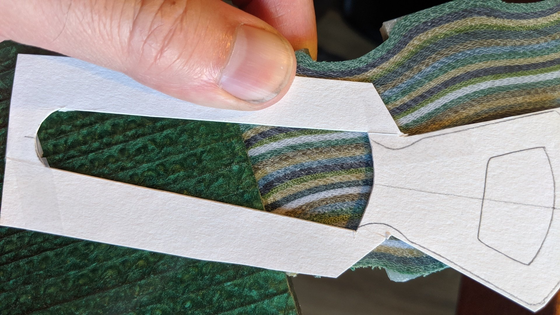

Selection of Materials

I am constantly searching for new materials to make each opener unique. I spend a lot of time looking at combinations of materials before selecting a final design. For custom openers, I work with the customer to make their vision come to life.

I finish each opener so that it feels great in the hand and brings out the beauty of the materials.